WR1000 Traditional Tank Turning Rolls

WR1000 tons conventional welding rotator is a special welding machine for making the cooling tanks of the Westhouse nuclear power plant of the United States .

The Traditional Tank Turning Rolls is suitable for welding the longitudinal and round seams of tanks, the tanks were placed on the tank turning rolls. The wheels center to center distance was adjusted by workers according to the diameter of the cylinder. Conventional tank turning rolls are usually used for heavy-duty tanks with large diameters

Conventional tank turning rolls also known as: Conventional Rotators, Conventional Welding Rotators, Tank Rotators, Welding Rotators, Welding Tank Turning Rolls,Tank Rollers, Welding Rollers, Welding Rolls, Vessel Rollers, Tank Rolls, Turning Rolls, Rotador Soldadura, Virador Soldadura, Rotores Tanques, Rotador Tanques, Rotador Tuberia, Rodillos Dirección, Rotores Tuberías, Rotores Cilindros, Rotador Soldagem, Rolos Giro

WR1000 conventional welding rotator use 4 special forging metal wheels for power and idler turning rolls , Metal wheels Center to Center distance may be adjusted by manual. The power wheels synchronous rotation driven by dual motors.

Working principle of welding rotator:

The welding rotator drives the rotation of tanks through the frictional force between the tanks and the wheels of rotator, and is combined with welding manipulator, welding power, etc. to achieve automatic welding of the inner or outer circumferential seams, fillet welds, and longitudinal seams of the welding components.

Advantages of adjustable turning rolls:

1. High safety: The adjustable turning rolls has a large distance between the rollers and a large angle between the center of the workpiece and the rollers, making it particularly suitable for large-diameter workpieces,.

2. Easy to operate: The position of the roller can be easily adjusted through manual screw, bolt displacement, or electric skateboard displacement to accommodate workpieces of different sizes, making the operation simple and convenient.

3. Multifunctionality: The adjustable turning rolls can not only be used for welding cylindrical bodies, but also for polishing, lining, and assembly operations. It can even be used in conjunction with other fixtures for assembling and welding conical, segmented, and non equal diameter rotating bodies, expanding its application range.

4. Safety protection: It has overvoltage protection and self-protection functions, fault display and storage functions, as well as automatic air switch short-circuit protection, ensuring operational safety.

Shopping Guide of Conventional Welding Rotator:

1、How to choose" Loading capacity of tank turning rolls " ?

Although the loading capacity safety factor of our welding rotator is over 1.3, but we still hope that the weight of tanks(cylinders) does not exceed 80% of our model. If the tank turning roll is used under the limit loading capacity for a long time, its service life will be reduced.

Taking WR100 welding rotator as an example: Design ultimate load capacity is over than 130 tons, safe loading capacity is 100 tons, the recommended weight of the cylinder is 80 tons .

2、Why do we require sufficient allowance for the load capacity of the welding rotator?

A set of tank turning roll is consists of an active rotator and a passive rotator. When the cylinder is placed on the two units, there may be a phenomenon of weight deviation. This will result in one of the rotator having a larger load capacity.

3、How to choose welding rotators for very long tanks ?

For longer tanks, we can configure multiple welding rotators, such as one active and two passive or multiple active and passive for supporting and driving.

4、How to choose a welding rotator for thin walled cylinder with large diameters and light weight?

This type cylinder can use an adjustable turning rolls, but it is best to use a dual drive self-adjusting turning rotator.

5、Why do large cylinders often use adjustable tank turning rolls?

Dual motor drive, with greater driving torque;Distance of two roller is larger, making it look safer;Suitable for a wide range of cylinder diameters

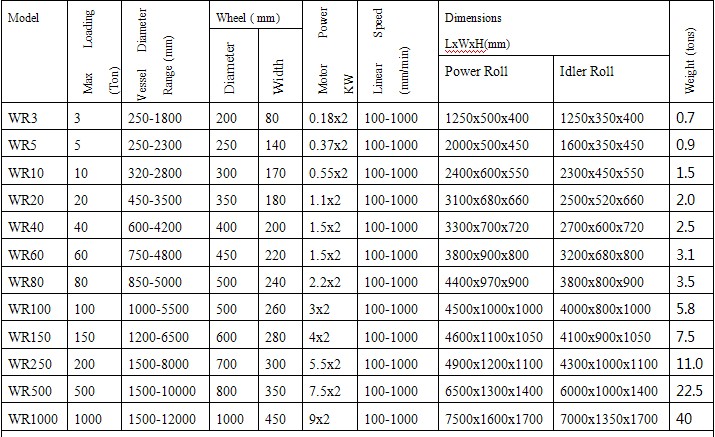

Main Technical Parameters

WR1000 / Metal wheels / 2 motors with reducers

WR1000 / Metal wheels / 2 motors with reducers