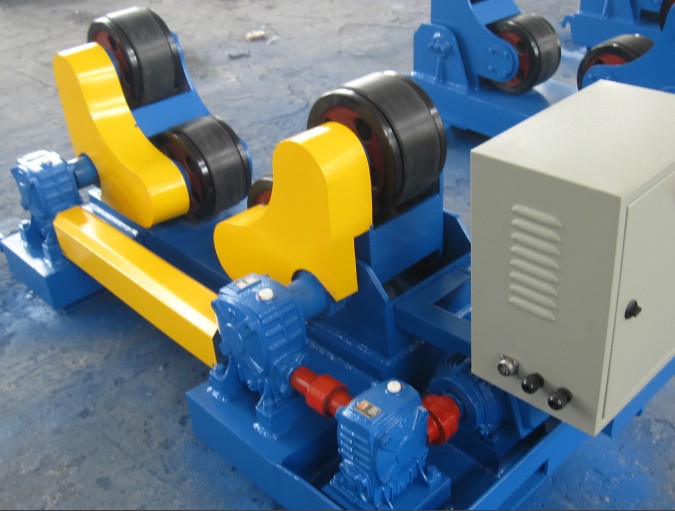

Self Aligned Tank Turning Rolls

Self-aligned Tank Turning Rolls is suitable for welding the longitudinal or circle seam of round tanks. Self aligning welding rotator has four motorized rollers which use worm gear reducers to drive the wheels synchronous rotation. the wheels of the self-aligning welding rotators can open by itself while the tanks were placed on the rotator. This type machine is widely used in thin thickness pressure vessel fabrications , wind power , small and large pipe ,boiler vessels ,shipyards and many more .

Self-aligned tank turning rolls also named as: Self aligned welding rotator,Self aligning welding rotators, Self opened welding rotator,Self adjusted turning rolls, Self alignment rollers, Self adjustment welding rollers, Self adjusting tank rolls, Tank turning rolls, Rotador de Soldadura Auto Ajustable, Virador de Soldadura Auto Ajustable, Virador de Tanques Auto Ajustable, Rotador de Tanques Auto Ajustable and Rotador de Tuberia Auto Ajustable

Shopping Guide of Welding Rotator:

1、How to choose" Loading capacity of tank turning rolls " ?

Although the loading capacity safety factor of our tanks welding rotator is over 1.3, but we still hope that the weight of tanks(cylinders) does not exceed 80% of our model. If the tank turning roll is used under the limit loading capacity for a long time, its service life will be reduced.

Taking SAR100 welding rotator as an example: Design ultimate load capacity is over than 130 tons, safe loading capacity is 100 tons, the recommended weight of the cylinder is 80 tons .

2、Why do we require sufficient allowance for the load capacity of the welding rotator?

A set of tank turning roll is consists of an active rotator and a passive rotator. When the cylinder is placed on the two units, there may be a phenomenon of weight deviation. This will result in one of the rotator having a larger load capacity.

3、How to choose welding rotators for very long tanks ?

For longer tanks, we can configure multiple welding rotators, such as one active and two passive or multiple active and passive for supporting and driving.

4、How to choose a welding rotator for thin walled cylinder with large diameters and light weight?

This type cylinder can use a set of self aligned tank turning rolls, but it is best to use a dual drive self-adjusting turning rotator.

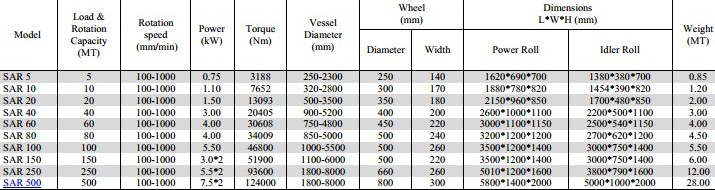

Main Technical Parameters

Notes:

Notes:

1 Remote control box(by hand):wire / wireless

2 Wheels material : Rubber with 2 metal wheels clamping / PU material / 45# forging steel

3 Control motor :one motor with 3 reducers / two motors with 2 reducers

4 Power / Idler moving : by hand / by motor

SAR10 / Rubber with 2 metal wheels clamping / one motor with 3 reducers

SAR60 / PU wheels / two motors with 2 reducers

SAR250 / 45# forging steel wheels / two motors with 2 reducers/ manual moving