5T - 60T Pipe Welding self - aligning Rotator with rubber rollers , tank turning rolls

Quick DetailE-mail : wxyijie@hotmail.com

- This series pipe welding rotators are self-alignment/self centering type with rubber rollers.

- Steplessly controllable rotary drives by means of A.C. or D.C. motor (on request) drive via self-locking worm gear reducers;

- Schneider or Panasonic inverter to realize VFD speed control and synchronous rotation of rollers;

- Heat treatment to main welding parts after welding; sand blasting treatment to main welding parts before painting;

- Roller distance is self-aligned and roller surrounding angle among 45°~110°;

1. Introduction

This series pipe welding rotators are self-alignment/self centering type with rubber rollers.

Our welding roller beds designed for maximum workpiece loads from 5T to 60T are used for the rotation and positioning of heavy, rotationally symmetrical workpieces like tanks, pipes or boilers for further machining or welding.

We also provide tailor-made pipe welding rotator according to your special requirements.

2. Main Parameters

Model

|

HGZ5

|

HGZ10

|

HGZ20

|

HGZ40

|

HGZ60

|

Max loading T

|

5

|

10

|

20

|

40

|

60

|

Suit diameter mm

|

Min

|

250

|

320

|

500

|

600

|

750

|

Max

|

2300

|

2800

|

3500

|

4200

|

5000

|

Rubber Roller mm

|

Dia

|

250

|

300

|

350

|

400

|

450

|

Width

|

100

|

120

|

120

|

120

|

120

|

Metallic roller mm

|

Dia

|

244

|

294

|

344

|

394

|

444

|

Width

|

20

|

25

|

30

|

40

|

50

|

Linear speed m/h

|

6--60

|

Speed Control

|

VFD

|

Motor power kW

|

0.75

|

1.1

|

1.5

|

3

|

4

|

Roller distance mm

|

900

|

1100

|

1350

|

1600

|

1800

|

Above are our standard models and parameters, and it can be designed and manufactured on request.

|

*We reserve the right to alter specifications without prior notice.

3. Main features

The standard models of our pipe welding rotators or roller beds have the following features:

- Steplessly controllable rotary drives by means of A.C. or D.C. motor (on request) drive via self-locking worm gear reducers;

- Schneider or Panasonic inverter to realize VFD speed control and synchronous rotation of rollers;

- Heat treatment to main welding parts after welding; sand blasting treatment to main welding parts before painting;

- Roller distance is self-aligned and roller surrounding angle among 45°~110°;

- All motion parts have lubrication system;

- Main electric elements are ABB/Siemens brands;

- Hand pendant with Forward-Stop-Reverse and speed potentiometer are standard;

- Lifting lug on the base of roller bed;

- Standard color:

Optional features:

- Roller material options: Metallic or PU roller;

- Undercarriage/travel boogie;

- Interface for integral control with welding column&boom;

- Foot switch;

- Servo drive;

- Anti-explosion motor&control panel;

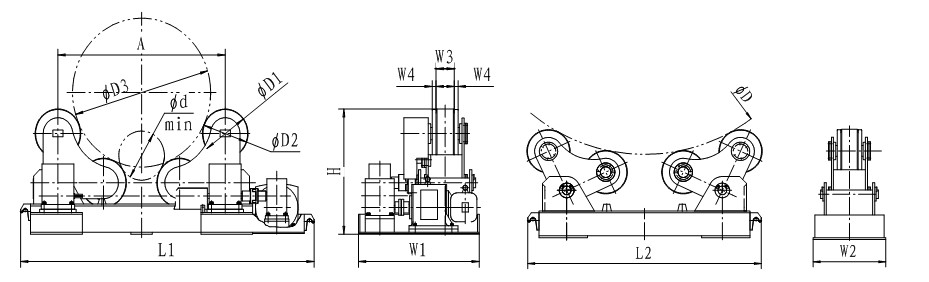

4. Structure drawing

5. Supply range

- Driving turning roll 1set

- Idle turning roll 1set

- Electric control system [including 1piece of electric control cabinet, 1piece of remote control box with cable 6m] 1set

- Technical documents (with manual book, conformity certificate, packing list, etc) 1set