MIG/ TIG / FCAW Welding Type With Linear Guider High Quality Welding Manipulators

MIG : Metal Melting Inert Gas Arc Welding

TIG : Tungsten (Non Melting) Inert Gas Arc Welding

FCAW :Fluxed Cored Arc Welding

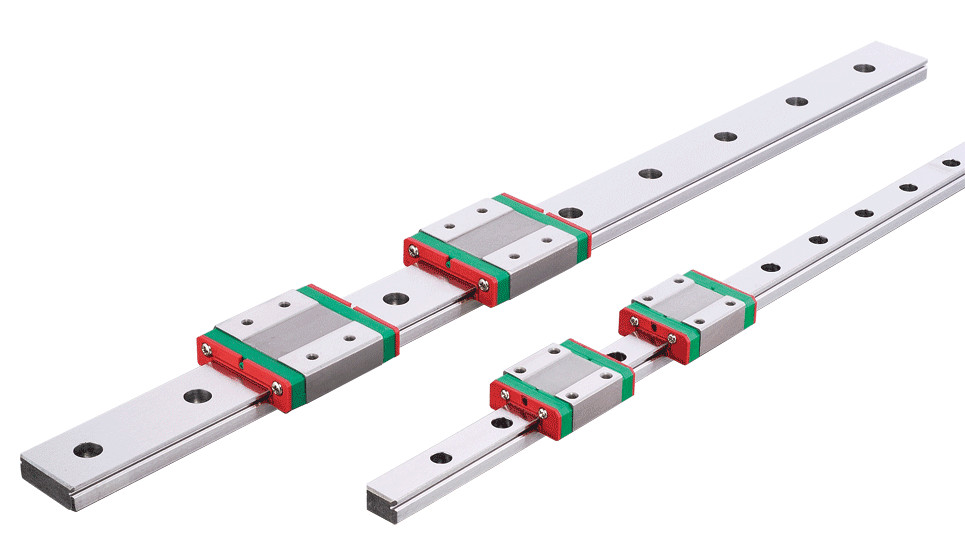

The wire diameter of these welding type is not so big, diameter often no more than 1.6mm .So the welding manipulator must have high accuracy , especially welding boom must be very smoothly while retracting . We often use linear guider to ensure this function .

Column boom welding manipulator detail description:

- Absorbing state of the art welding technics both inland and abroad,column boom welding manipulator is esstial part of pipe automated welding center.

- There are a number of designs for the columns, such as the stationary type, the stationary and rotating type, and the all orientation type.

- The movement of the boom is adopted with frequency conversion control. Good in mechanic precise,accurate in positioning.

- PLC programming controller is optional.

- Depends on pipe technics craft, the column boom welding manipulator is able to equip with SAW, TIG, FCAW etc welding machine.

- Used together with welding rotator or welding positioner, the column boom welding manipulator is widely used in industries as boiler, pressure vessel, petro-chemical machinery for welding of inner and outer longitudinal seams and circumferential seams.

- It has the advantage of in advanced structure,complete function, easy operation, which ensures improving of welding quality.

- According to the requirement, it can be adopted welding seam tracing and monitoring, welding flux recovery and feeding device.

Feature of the column boom welding manipulator:

- Boom end equipped with electric cross slides,which can adjust position of welding head.

- Automatic flux feeding, recovering devices, wire feeder device, working platform and chair are ptional.

- Stretching of cross boom adapts AC frequency converter stepless speed control and run with steady speed.

- Automatic column boom welding manipulator can be adopted with various welding power (Chinese or international famous brand) .

- Chain break-resistant and anti-slip device in boom to guarantee safety.

- Braking device can ensure column work in safe environment.

- Customization requirements are acceptable.

Main parameter of column boom welding manipulator:

Model

|

LH2020

|

LH3030

|

LH4040

|

LH5050

|

LH6060

|

Structure:

|

Travel & Rotation

|

Boom horizontal stroke : mm

|

2000

|

3000mm

|

4000mm

|

5000mm

|

6000mm

|

Boom vertical stroke : mm

|

2000

|

3000mm

|

4000mm

|

5000mm

|

6000mm

|

Boom horizontal speed :mm/min

|

150-1500

|

150-1500

|

150-1500

|

150-1500

|

150-1500

|

Boom vertical speed : mm/min

|

1000

|

1000

|

1000

|

1000

|

1000

|

Boom horizontal motor power :kW

|

0.55

|

0.55

|

0.55

|

0.55

|

0.55

|

Boom vertical motor power :kW

|

2.2

|

2.2

|

2.2

|

3

|

3

|

Column rotating angle

|

±180°

|

±180°

|

±180°

|

±180°

|

±180°

|

Column rotating speed- Optional :rpm

|

0.75

|

0.75

|

0.75

|

0.75

|

0.75

|

Column rotating motor-Optional : kW

|

0.75

|

0.75

|

0.75

|

0.75

|

0.75

|

Column rotating locking method

|

By manual

|

Boom end max. loading

|

100kg

|

Benefits:

The standard column boom welding manipulator has several benefits over welding the part manually, including:

- Able to achieve consistent weld results;

- Able to maintain weld head over weld joint in a stable position during the weld;

- Increases arc-on time and overall productivity;

- Provides ability to have multi-weld stations using only one weld head, increasing your return on investment;

- Reduced operator fatigue;

- Reduced consumable costs;

- Ability to have two welding process at one welding station by using both ends of the boom

These benefits greatly reduce the time to prepare a part for welding and the time to finish a part after welding. Also, rework time will be reduced and part scrap will be cut.