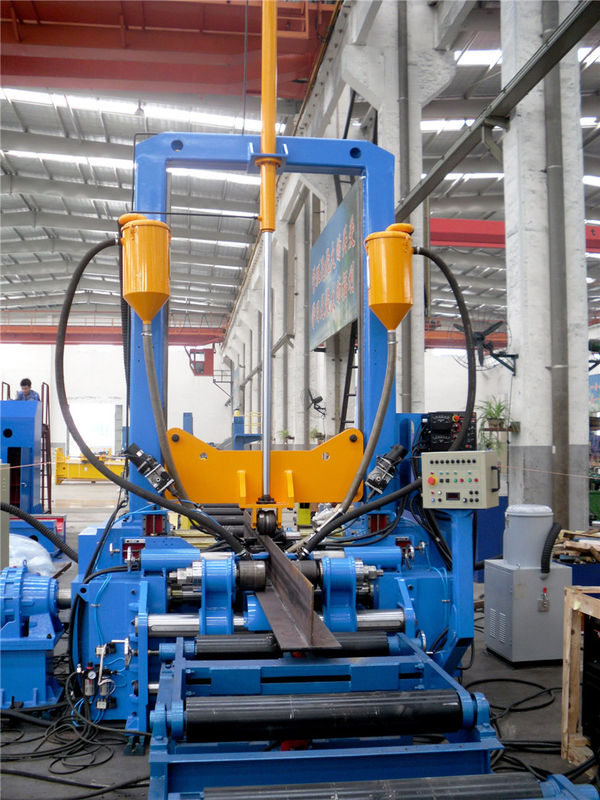

H-beam Assembling-Welding-Straightening Integrate Machine

All-in-one h-beam assembling, welding and correction are three functions of set equipment with the integration of comprehensive specialized equipment, compared with the traditional equipment shall be provided by the group set spell machine, gantry welding machine and the flange straightening machine three devices to complete on this device, and the effectiveness of blanking plate through auxiliary equipment into the host, the abdominal cavity open device button can be arrived at the completion of the finished product at once process to reduce human

intervention in the middle. Significantly increase the production efficiency, reduces the equipment cost and labor input, saved the space equipment installation, h-beam is efficient production and the best production equipment T section steel.

H-beam assembling-welding-straightening machine is comprehensive specialized equipment which centralized three function in one,compare with the traditional equipment shall be provided by assembling machine,gantry type welding machine and flange straightening machine three devices to complete on this devise,the effectiveness of blanking plate through auxiliary equipment into the host,the abdominal cavity open device button can be arrived at the completion of the finished product at once process to reduce human intervention in the middle,

significantly increase the production efficiency,reduces the equipment cost and

labor input,saved the space equipment installation,H-beam is efficient production

and the best production equipment T-beam.

2. Technical specification:

Speed adjust:AC frequency conversion stepless speed regulation

Electrical control : PLC automatic control

Web plate height: 160-1500 mm

Web plate thickness: 6-14 mm

Flange plate width: 200-800 mm

Flange plate thickness: 6-20 mm

H beam length: 4000-15000 mm

H beam forward speed: 0.35-3 m/min

Flux recovery and transport capacity: 100 L

Main driven power: 4 kW

Conveyor rollers power: 4 x 0.55=2.2 kW

Flux recovery and transport power: 2 x 3=6 kW

Pump station power: 5.5 kW

Hydraulic working pressure: 12 MPa

Welding power: MZ-1000